CMMS, a tool to improve corporate sustainability development.

Optimized resource management

Effective asset management is at the core of sustainable operations. By optimizing resource utilization, extending equipment lifespans, and reducing waste, asset management ensures businesses operate efficiently and responsibly.

The CMMS (Computerized Maintenance Management System) allows for more precise inventory and material resource management, reducing surplus and shortages that can lead to waste. Thanks to advanced features, equipment is regularly checked, preventative maintenance needs are identified to intervene at the right time, and before equipment becomes faulty or excessively energy-consuming. This proactive management helps businesses minimize energy and other resource consumption.

Waste reduction

Additionally, CMMS helps to limit waste production, as well-managed maintenance significantly impacts the lifespan of equipment. This approach supports a circular economy where goods are used more sustainably. The CMMS tracking and alert features also help to regulate emissions and control processes that may pollute the environment, thus helping to reduce the company’s ecological footprint.

Get to know CMMS in just 2 minutes

Optimization of production processes

A case study from Val’Up: CMMS and the reduction of energy expenditures.

The sorting center, Val’Up in Belgium, has implemented CMMS. The maintenance manager explains:

An installation well maintained in terms of lubrication, localization of air leaks, control of energy recovery circuits, etc., consumes significantly less energy, and CMMS ensures this.

The maintenance manager is very clear about the preventive processes of CMMS, for:

- Automatically generating work orders with precise instructions for the controls to be carried out.

- Creating work orders with checklists for closing or opening a plant, for example.

- Ensuring efficient stock management to avoid any wastage.

- Developing efficient analytics to anticipate and adapt maintenance slots to optimize off-peak hours.

- The collection of vibratory data is particularly valuable for identifying future issues and better controlling costs.

This proactive approach not only reduces energy expenditures but also contributes to the achievement of the company’s environmental goals, in line with societal expectations of ecological responsibility.

Social and cultural impact of CMMS

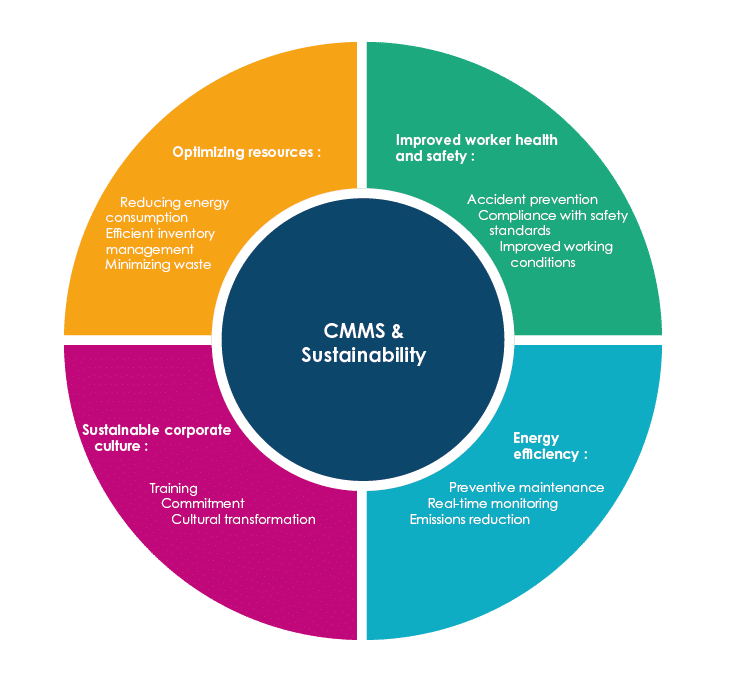

CMMS doesn’t just focus on optimizing resource use and energy efficiency; it plays a crucial role in improving worker health and safety, as well as in shifting corporate culture toward greater sustainability.

Improved workplace safety and health

The integration of CMMS into industrial processes significantly contributes to accident prevention and risk reduction in the workplace. Implementing regular and proactive maintenance helps keep equipment in optimal working condition, avoiding breakdowns that could endanger operators. Moreover, CMMS facilitates compliance with existing safety standards and ensures rigorous tracking of maintenance procedures, which enhances the overall safety of the work environment.

Cultural shift towards sustainability

Beyond technical aspects, CMMS positively influences company culture. CMMS supports employee engagement in the company’s sustainability initiatives. By integrating environmentally friendly maintenance practices into their daily routines, employees become active participants in reducing the ecological impact of their work. Regular training sessions and learning modules integrated in CMMS reinforce this culture of consciousness and environmental responsibility. This cultural evolution is not limited to isolated initiatives but becomes an encompassing movement where each company member is an actor of change.

How to successfully implement CMMS?

Main obstacles to implementing CMMS

- Resistance to change: employees may fear the transition will disrupt their work habits or require new skills to be acquired.

- Integration with existing systems, which can lead to delays and frustrations.

- Data management: CMMS relies on significant amounts of data regarding equipment, maintenance processes, and operational performance. Ensuring data quality and integrity is essential for system effectiveness. However, data collection, entry, and management may be complex and require additional resources.

Our tips to overcome obstacles and ensure a successful project

- Resistance to change: involve employees from the beginning of the process. Organize training and awareness sessions to explain the benefits of CMMS and how it can facilitate daily work.

- Integration with other systems: a phased approach can be beneficial. Instead of implementing everything at once, it might be wise to start with specific modules or features, and then gradually add more elements as the company adapts to the new technology.

- Data management: establish clear procedures and quality standards to ensure accuracy and consistency of collected information.

Moving towards a sustainable enterprise with CMMS

CMMS contributes to the levers set up by companies in a corporate social responsibility approach: optimized resources, improved energy efficiency, enhanced worker health and safety, and a transformed company culture. CMMS is proving to be a useful tool in tackling the environmental and social challenges we face. By overcoming the barriers to its adoption and with a sustainability-focused approach, companies can improve their operational performance while also contributing to a more sustainable future.