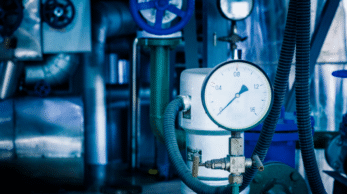

Subjected to some of the harshest usage conditions in the industry, extraction equipment requires special attention. Industrial maintenance in this sector represents a significant challenge as it must imperatively balance productivity and safety. Extractive companies can rely on CMMS to deploy their large-scale maintenance strategy and maximize preventive maintenance.

The challenges of maintenance in the extraction sector

The specific constraints of the extraction sector make its industrial maintenance particularly sensitive. The operating conditions of the equipment – often hostile environments including dust, humidity, vibrations, or extreme temperatures – generally accelerate wear and tear. Maintaining machines is all the more important for industrialists, as they represent a major investment and a key element of the production chain.

Directly linked to these conditions, the availability of equipment is a constant concern for extraction industrialists. The sector’s margins largely depend on the continuity of operations, as any breakdown can lead to a complete site shutdown. To prevent these situations, industrial maintenance must be considered as part of a strategy rather than just a cost center.

Moreover, regulatory constraints strongly apply to the extraction sector, with omnipresent safety standards (ISO 45001, RGIE, ATEX 2014/34/EU) and environmental requirements (ISO 14001). Besides the risk of accidents, industrialists must, through maintenance, protect themselves from any legal sanctions. Compliance is therefore essential.

Finally, among the strong challenges of the sector is the constant optimization of resources. Extraction sites, often far from urban centers, raise questions about the delivery of spare parts and the intervention of specialized technicians. Planning maintenance is essential to properly orchestrate operations and minimize logistical constraints.

Maintenance practices in the extraction sector

Over the years, the extraction sector has significantly evolved its industrial maintenance practices. Historically based on a reactive approach – interventions mainly occurring after a breakdown – maintenance must now be as anticipated as possible.

Several complementary approaches are generally necessary for good maintenance:

- Conditional maintenance: Based on the regular monitoring of key equipment parameters (vibrations, temperatures, oil analyses), it involves intervening only when signs of degradation are detected.

- Reliability-centered maintenance (MTBF): This approach, which includes preventive maintenance, involves identifying potential failure modes and their consequences. The most priority maintenance activities for the continuity of operations are thus executed.

- Corrective maintenance: Corrective maintenance remains relevant in the extraction field. It aims to address unforeseen breakdowns and limit downtime.

Companies in the sector generally employ a combination of these approaches, in proportions depending on the criticality of each asset. IoT or predictive analysis solutions, as well as the use of a maintenance software, are then valuable supports for coordinating operations of all types and making faster decisions.

Adopting more preventive maintenance, an essential approach for the sector

The extractive sector tends, as much as possible, towards increasingly preventive maintenance. The principle of this maintenance is indeed the most suitable for the sector’s issues and significantly streamlines operations.

In a high-constraint environment, preventive maintenance allows to:

- Significantly extend the lifespan of equipment

- Eliminate a large part of unplanned shutdowns

- Optimize the energy consumption of installations

- Improve operator safety by limiting field risks

The implementation of a preventive maintenance program generally relies on the combination of several actions. The most common of these will be periodic inspections, a schedule of planned interventions during periods of lower activity, and the preventive replacement of critical components at predefined intervals.

The impact of preventive maintenance on the extraction industry is significant, with equipment availability rates that can exceed 95%, compared to less than 80% for those favoring a reactive approach. This anticipation capability, however, requires the adoption of a maintenance software: only a process automation solution can provide the sector with all the necessary reliability and responsiveness.

CMMS, capable of adapting to the specific needs of the sector

Created to specifically meet the needs of heavy industry, CMMS is still particularly suited to the complexity of extraction needs today. The maintenance software will thus include ideal features to ensure the preventive maintenance of extraction equipment. Field mobility, predictive analysis, and interoperability with industrial control-command systems are among the possibilities offered by the software to properly orchestrate industrial maintenance.

Asset and spare parts management

The maintenance software allows precise tracking of the inventory of equipment and their technical characteristics. It also facilitates the management of spare parts stocks on isolated sites. Information is always accessible to managers, who have complete visibility over the infrastructures.

Planning and tracking interventions

The strength of CMMS is its orchestration capability of preventive maintenance. Predefined schedules regulate the generation of work orders. This automation results in better planning of resources – both human and material. Real-time tracking of interventions provides greater coordination capacity between maintenance and production teams and a considerable time saving.

Data analysis and decision support

Analysis is one of the major assets of maintenance software. With CMMS, it will be possible to consult breakdown histories, intervention costs, and performance indicators (MTBF, MTTR) chosen by the user. Maintenance is carried out within a rigorous framework and based on criteria specific to each company in the sector.

Technical documentation and regulatory compliance

The centralization of technical documentation and intervention reports is essential, both for quickly transmitting information and for meeting the sector’s very strict regulatory requirements. Collecting maintenance data in one place simplifies audit phases, but also on-site communication and real-time knowledge of equipment.

Mobility and access to data in the field

Finally, the mobile features of CMMS are among the most useful software evolutions for the extraction sector. Using an application in the field, even in areas with limited connectivity, provides continuous access to key intervention information and speeds up maintenance operations.

These features result in significant advantages for the extraction sector. In addition to the notable extension of equipment life, there is a significant reduction in downtime, significant cost optimization, and a complete view of the state of machines at any time. Flexible, CMMS adapts to the most specific needs and integrates seamlessly into daily maintenance practices.