The new CMMS enhances service collaboration and boosts operational efficiency

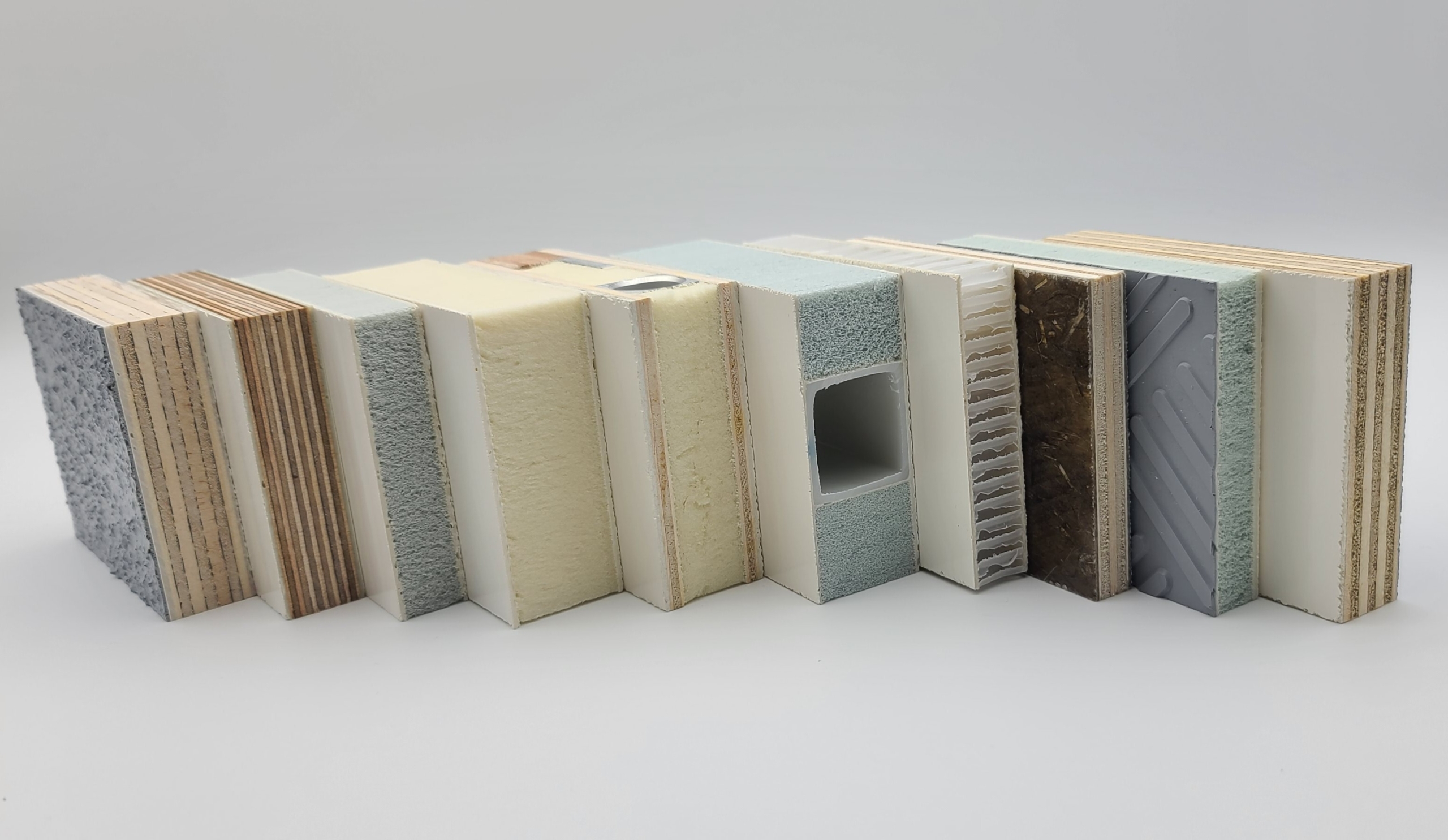

Founded in 1957 in Calonne-Ricouart (62), Carlier Plastiques & Composites (CA 38M, 109 employees) is an ISO 9001 certified manufacturer of composite panels and partitions. Its business (industrial bodywork, trailers, etc.) mainly spreads across France, Germany, and the UK. A long-time client of OptiMaint, the company decided to migrate to the new DimoMaint OM solution and take advantage of the flexibility offered by a Sage X3 connector. The goal: to provide management control with a clear view of maintenance costs. Jérôme BERNARD, the head of Information Systems, led the CMMS integration. He discusses the project’s rollout, implemented within six months, outlines the various flows between ERP and CMMS, and shares the numerous benefits. This strategic choice illustrates the company’s commitment to investing in innovative tools to improve performance and meet the increasing demands of a highly competitive sector.

A strategic migration to increase availability and yield of assets

Jérôme BERNARD explains that Carlier Plastiques & Composites aimed to transition to the new DimoMaint OM CMMS for a refined tracking of interventions and critical parts associated with diverse assets, with the idea of being able to place orders through the Purchasing section at the right time. This decision was made for three major reasons:

- Keeping the data history,

- Maintaining the practical aspects of OptiMaint,

- Integrating the X3 connector for interfacing with purchasing and accounting flows.

This last point was critical in validating the project with the management team.

A project planned with precision

Usually, the choice of a connector is linked to implementing a new ERP or to the first-time integration of a CMMS. In this respect, it’s simpler to start from scratch. Therefore, Carlier Plastiques & Composites had to transfer all the legacy data from OptiMaint and standardize it between the CMMS and the ERP—a somewhat laborious, yet essential, step. Jérôme BERNARD tested DimoMaint OM on a database in March 2024: “We were on Sage X3 v11 in an Oracle database. Once the flows could operate, we went live in mid-July seamlessly in just a few hours, allowing for comprehensive data recovery and rapid availability. The connector went live in December.”

Carlier Plastiques & Composites originally manufactured composite tanks, so items and suppliers had to be upgraded in both CMMS and Sage X3. It was also essential to link all supplier codes to ensure the correlation between 20,000 items and 1,500 suppliers, not to mention basic data such as units of measure, payment methods, etc. These operations took three days in a test environment, followed by four days in the production environment: this step was crucial to the success of the project.

Controlled flows between ERP and CMMS

The CMMS manages work orders (WO) required for stock withdrawals. A withdrawal request in X3 automatically triggers a workflow. Spare parts are issued with analytical data based on the technician’s input. Purchase requests, once converted into orders in DimoMaint OM, are automatically transferred to Sage X3, where they are validated by the Purchasing department. Upon receipt and automatic confirmation in Sage X3, the parts are added to inventory in both the ERP and the CMMS. The solution stands out for its user-friendly interface and advanced features, perfectly aligned with the needs of Carlier Plastiques & Composites. It ensures enhanced traceability of maintenance activities and equipment, along with accurate KPIs to support efficient resource management and optimization.

A transition providing greater fluidity to internal services

According to Jérôme BERNARD, implementing the new CMMS strengthens interdepartmental collaboration through connected and integrated features.

- Maintenance teams benefit from a centralized, high-performance tool for managing interventions and WOs. “In terms of KPIs for maintenance, we primarily track the number of WOs completed,” notes Jérôme BERNARD. The new Maintenance Manager, who joined mid-project, can fully dedicate himself to his teams and his core profession, relieved from the time-consuming management of purchasing flows. The focus on preventative maintenance is growing. Eventually, implementing TPM (Total Productive Maintenance) is under consideration.

- Administrative teams enjoy increased automation, notably in invoice processing and cost tracking. Thanks to the DimoMaint OM / SAGE X3 connector, the purchasing process is now linked to the standard flow of X3. This also makes the storekeeper’s job easier, entering receipts only in one system. Management control can better allocate costs by asset and production line. This allows for insights into which areas are incurring expenses, and where the parts from stock withdrawals are allocated when issuing a WO. A valuable decision-making tool: “We have a clear vision of an asset’s cost on a production line. In the long run, we plan to consolidate all our stores into one physical location for better stock management, automatic replenishments, and so on,” explains Jérôme BERNARD.

- The Purchasing department relieves the Maintenance Manager by directly placing orders with suppliers. Previously, orders weren’t linked to the ERP SAGE X3, hence this department had no visibility over maintenance expenses and suppliers.

- During the support phase, servers were also updated. Since going live, IT benefits from product tracking through DIMO’s ticketing tool. DIMO’s service center is highly responsive.

An intuitive CMMS and enhanced integration with Sage X3 for multiple benefits

The full integration with Sage X3 brings Carlier Plastiques & Composites in summary:

- Automated data sharing between CMMS and ERP, especially for tracking costs, inventory, and operations.

- Optimized management of purchasing processes, with smooth data transfer from maintenance to Sage X3 for rapid and reliable processing.

- Real-time synchronization, avoiding duplicate entries and reducing errors.

- Increased productivity, thanks to a consolidated view of all operations.

“This project has been a real success thanks to the involvement of the Carlier Plastiques & Composites teams and the support from our partner DimoMaint,” ultimately assesses Jérôme BERNARD.

Interested in learning more about Carlier Plastiques & Composites, an innovative player in composite solutions and its transition to an intuitive and dynamic CMMS?