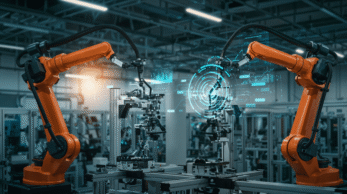

In a medical environment, equipment failure is not an option: for facilities committed to continuous care, maintenance is a constant concern. Healthcare facilities must ensure uninterrupted operation of devices while also complying with strict regulations.

The latest tools, including CMMS, help structure biomedical maintenance around two complementary axes: preventive maintenance and predictive maintenance.

By combining these two strategies, medical facilities can implement controlled maintenance, rigorous and tailored to the needs of each asset.

Biomedical Equipment Maintenance: Precision as a Necessity

The biomedical sector involves highly sophisticated assets, whose analyses are essential to the care process. Medical imaging devices, patient monitoring systems, laboratory equipment, or life-support systems all require specific maintenance tailored to their complexity. Hospital technical services face a wide range of tasks and must intervene on these devices with precise information.

Industrial maintenance in the sector is also governed by very strict regulations. In France, the decree of October 3, 1995, mandates regular quality checks on medical devices. ISO 13485 defines the quality management system requirements for the medical device industry. With these regulatory frameworks, professionals must meet high traceability requirements for technical interventions, adding to the other maintenance challenges.

In industrial maintenance, medical facilities generally prioritize:

- Patient safety: Preventing failures protects patients’ lives and ensures their diagnoses are never compromised.

- Continuity of care: Some treatments depend on the availability of critical equipment, and a breakdown can disrupt the entire service.

- Cost control: The biomedical asset pool represents a significant investment, and its lifespan directly depends on the quality of its maintenance. Proper maintenance should maximize this usage time.

- Legal responsibility: In case of an incident, proof of compliant maintenance protects the concerned facility.

Biomedical services also face specific constraints such as:

- Sterile environment: Technical interventions must comply with strict hygiene protocols.

- Specialized training: Technicians must master ever-evolving medical technologies.

- Coordination with care teams: To avoid impacting care, maintenance interventions must be scheduled during periods of low activity.

In this context, facilities have no choice but to meticulously document and standardize their procedures. Preventive maintenance is particularly relevant here, as it anticipates failures and meets the need for availability while simplifying the organization of operations.

The Impact of Preventive Maintenance on Patient Care

The primary goal of biomedical maintenance is, of course, the quality of analyses and patient care. A faulty or poorly calibrated asset can lead to diagnostic errors or ineffective treatments. The reliability of biomedical equipment directly determines the reliability of medical procedures.

Preventive maintenance plays a crucial role here. It relies on anticipation based on established scenarios. By anticipating potential failures, it significantly reduces the risk of care interruptions. Additionally, the quality of maintenance also impacts patients’ hospitalization duration. Properly functioning equipment leads to faster diagnoses and more effective treatments, reducing the time patients spend in the hospital. This reduces coordination and costs for medical facilities, which often face significant budget constraints.

Although paradoxical, balancing profitability and quality of care is a constant concern for medical facilities. Well-organized preventive maintenance can manage costs and anticipate pitfalls, ensuring the medical journey remains smooth.

CMMS and Other Technological Innovations Supporting the Sector

The main tool for preventive maintenance, CMMS provides structure and precision to the management of a biomedical asset pool. The software’s functionalities are as varied as:

Asset Inventory and Tracking

CMMS provides access to technical specifications, location, intervention history, and regulatory documentation of devices. This traceability facilitates audits and certification for medical facilities.

Preventive Maintenance Planning

The maintenance software automates intervention planning based on various criteria: calendar, usage counters, or manufacturer recommendations. Scheduled alerts help anticipate the need for spare parts and technical resources.

Documentation and Procedures

CMMS centralizes all maintenance procedures. Technicians instantly access intervention procedures specific to each asset. This ensures interventions comply with standards and manufacturer recommendations.

Stock and Supply Management

Using maintenance software helps optimize spare parts management during interventions and maintain daily stock levels aligned with actual needs.

Reporting and Analysis

The software provides complete visibility into the state of the biomedical asset pool. Indicators such as availability rate, maintenance costs, and failure frequency are invaluable for optimizing industrial maintenance strategies.

Predictive Maintenance and Innovations Complementing CMMS

While CMMS forms the foundation of preventive maintenance, it is now evolving into a more intelligent and proactive dimension through the integration of advanced technologies. In this context, predictive maintenance emerges as a natural extension, anticipating failures before they occur by leveraging real-time data and its analysis. CMMS thus fits into a broader technological ecosystem enriched by innovations such as:

Internet of Medical Things (IoMT)

Connected sensors installed on medical devices transmit real-time operational data to CMMS for more informed anomaly detection.

Artificial Intelligence

Artificial intelligence now analyzes historical maintenance data to identify patterns and anticipate failures. This predictive approach optimizes preventive maintenance schedules based on actual asset usage.

Augmented Reality

This technology guides technicians during complex interventions by overlaying visual instructions on the actual asset. It enhances both the precision of interventions on sophisticated devices and the transfer of information between technicians.

Maintenance Software: Concrete Benefits for Biomedical Maintenance

Using CMMS has immediate benefits for medical facilities, as the software enables:

- Close monitoring of interventions: Always accessible documentation, real-time maintenance information, and tracking tickets are all readily available through CMMS. Visibility is complete from start to finish.

- Customized maintenance (and software): The maintenance software facilitates customization according to each facility’s procedures and integration with internal tools. Communication is streamlined among technicians, biomedical engineers, healthcare staff, and administrators, ensuring maintenance respects everyone’s operational constraints.

- Enhanced mobility and technician responsiveness: Mobility increases the agility of maintenance operations. On-site, technicians access real-time asset history, technical procedures, and available parts, significantly reducing intervention times. This responsiveness also leads to a notable decrease in the downtime of medical equipment.

- Simplified maintenance evolution: Regularly updated, CMMS supports healthcare facilities through changes. Procedures adapt seamlessly to new needs, and maintenance continually improves with shared team feedback.

When properly implemented, CMMS adapts to biomedical environments rather than the other way around. The solution integrates with each facility, meeting immediate needs and long-term expectations. In this way, maintenance software becomes a driving force for quality care.